- Open Hours: 7*24 H

- 0574-88053200 / +86-13732112378

What is Carbon Steel?

First, let us know what is carbon steel. Carbon steel is an iron-carbon alloy with a carbon content of 0.0218% to 2.11%. and it is one of the most popular materials in the world of manufacturing, due to its incredible properties. It also generally contains small amounts of silicon, manganese, sulfur, and phosphorus. The higher the carbon content, the higher the strength and the hardness.

As an experienced factory and supplier, SHENGFA Hardware provides high-precision carbon Carbon Carbon Steel Investment Casting Parts to more than 30 countries and regions around the world.

BENEFITS OF CHOOSING CARBON STEEL

Carbon steel an extremely popular option for investment casting, as it has a wide range of applications in many industries. Due to its ferromagnetic properties, carbon Carbon Steel Investment Casting Parts are particularly useful for motor and electrical appliances. Carbon steel is very safe and durable. Besides, it has a high level of structural integrity. All those features that add to its popularity and make it one of the most created alloys in the world.

WHAT IS INVESTMENT CASTING?

Investment castings, also known as lost wax castings, are formed by a traditional process, which has been used for centuries to produce detailed, intricate metal parts and components. The full process of investment casting includes Metal die construction, Wax pattern production, Mold creation, Pouring, Cooling, Shakeout and finally Finishing. Compared to other manufacturing methods, it is a cost-effective way of producing intricate products, providing significant design flexibility, with excellent dimensional accuracy and surface finish.

SHENGFA Hardware provides advanced carbon steel and low alloy castings for demanding modern industries. We produce precision carbon Carbon Steel Investment Casting Parts with industry-leading tolerances and desirable mechanical properties.

Product Parameters

Material

Carbon steel, alloy steel, stainless steel, copper Alloy

Process

Investment (lost wax) casting + CNC machining

Casting dimension tolerance

CT7

Casting surface roughness

Ra 12.5 um

Casting weight range

0.1-90 kg

Casting Size

Max linear size: 1200 mm, Max diameter size: 600 mm

Machining Precision

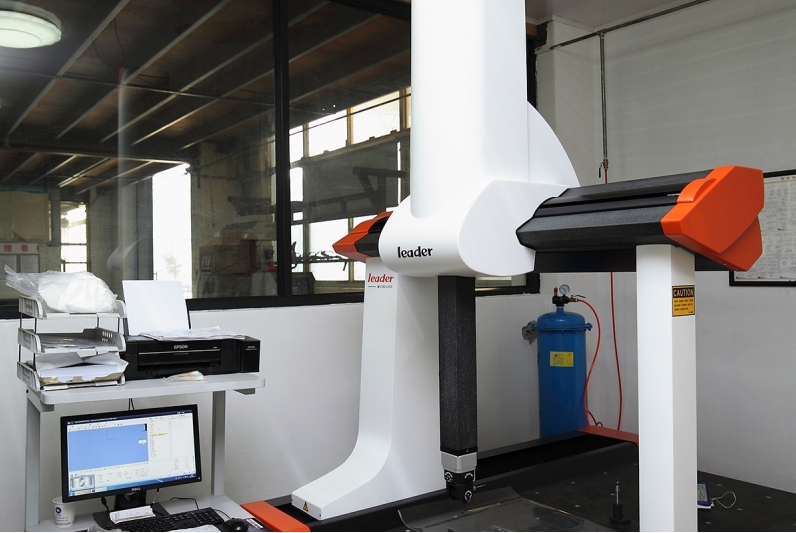

Positioning accuracy 0.008 mm, Rep. position. accuracy 0.006 mm

Machining surface roughness

Ra0.8 ~ 6.3 um

Max Travel Of Spindle

1900 mm x 850 mm x 700 mm

Max Turning Diameter

830 mm

Material standard

GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR

Surface treatment

KTL (E-coating), Zinc plating, Mirror Polishing, Sand Blasting, Acid pickling, black oxide, Painting, Hot galvanizing,Powder coating, Nickel plating.

Service available

OEM & ODM

Quality control

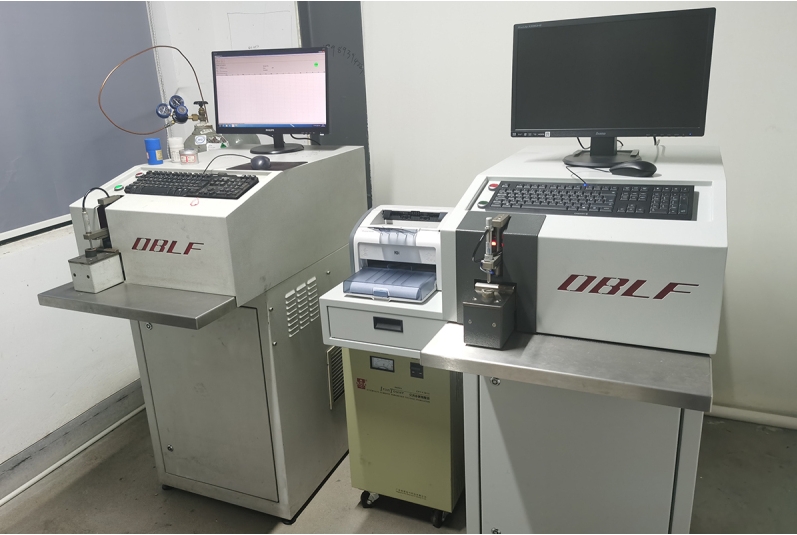

0 defects,100% inspection before packing

Application

● Aerospace and defense

● Power generation

● Automotive

● Oil and gas

● Space exploration

● Medical/orthopedics

● Agriculture

● Construction

● Commercial and consumer products

Send Email

Send Email 184731149

184731149